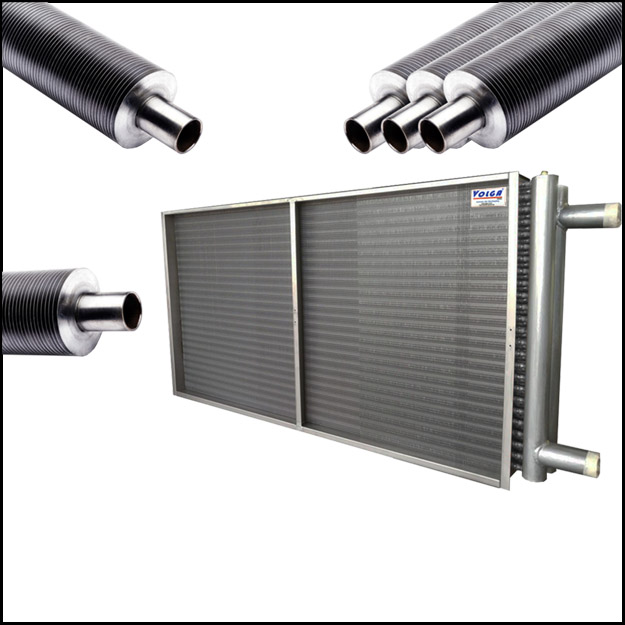

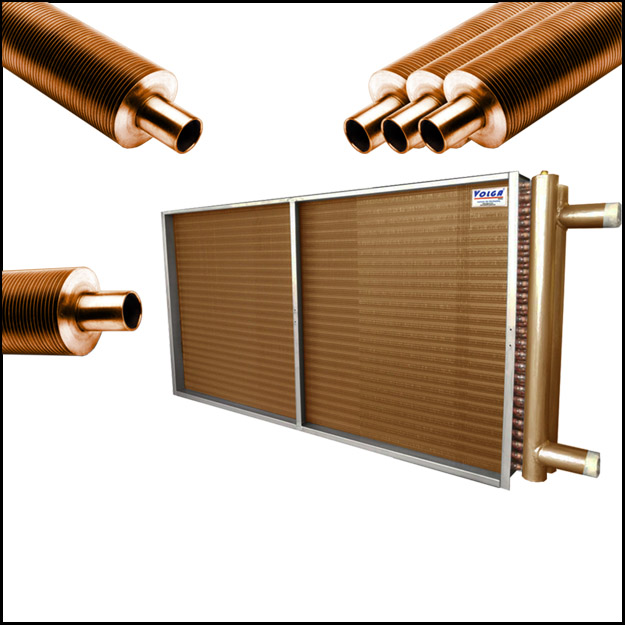

Spiral Finned Tube SS. Coil

VOLGA HVAC® – Spiral Finned Tube Heat Exchanger

Stainless Steel Tube Type – High-Efficiency Heat Transfer for Air Cooling

Product Overview

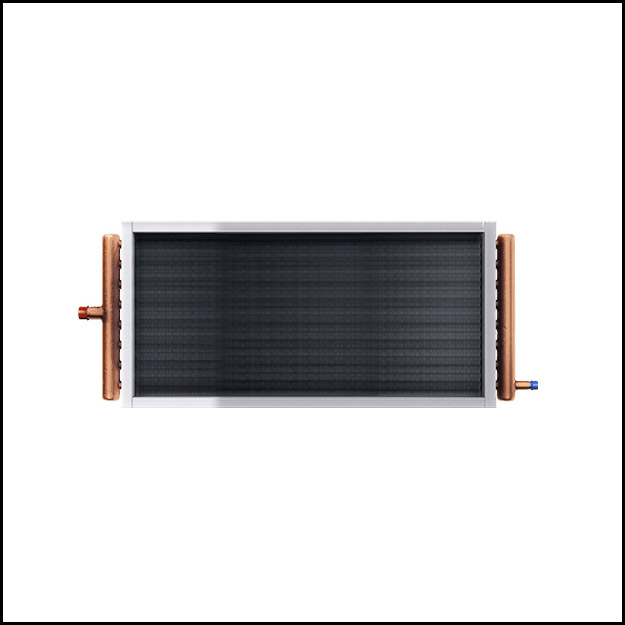

The VOLGA HVAC® Spiral Finned Tube Heat Exchanger with stainless steel tubing offers robust, corrosion-resistant performance for demanding air-cooling environments. Featuring precision-wound copper fins on SS304 or SS316 tubes, this design provides excellent thermal efficiency with low air resistance.

Design & Construction

-

Tube Type: Stainless Steel SS304 / SS316

-

Fin Material: Special copper, tension-wound for enhanced thermal contact

-

Fin Thickness: Ranges from 0.010” to 0.030” depending on application requirements

-

Fin Geometry: Tapered spiral profile for superior heat transfer surface contact

-

Thermal Cycling Resilience: Independently finned tubes allow free expansion, minimizing mechanical stress and maintaining long-term reliability

-

Airside Efficiency: Optimized for low drag and uniform air distribution

Key Benefits

-

Excellent corrosion resistance for harsh or wet environments

-

Superior thermal transfer efficiency

-

Reliable under frequent thermal cycling and continuous operation

-

Customizable specifications for fin and tube materials, thickness, and layout

Applications

-

Air-cooled industrial systems

-

Condenser or cooler retrofits

-

Stainless-steel-based OEM coil solutions

-

Corrosion-critical air handling environments

Certifications & Standards

Brand: VOLGA HVAC®

Manufacturing Standards:

-

ISO 9001:2015 – Quality Management

-

ISO 45001:2018 – Occupational Health & Safety

-

CTI Certified

-

ASO QCMS / CSAMS / OHSMS

Custom Engineering Support

Let us assist you in selecting or designing your ideal spiral finned tube heat exchanger by providing:

-

Operating temperature and air velocity requirements

-

Desired tube material and fin geometry

-

Environmental conditions and corrosion resistance needs

-

Mounting or retrofit constraints